Total Control, Quality.

Production Excellence

Equipped with cutting-edge machinery and robust processes, our facilities deliver consistent quality, enhanced productivity, and sustainable manufacturing across every stage of production.

800+

No. of machineries we use

1.5 million + Sq ft leather monthly

Leather Production Capacity

1000+

No. of workers

Leather Expertise

Our Tannery

Located in the Calcutta Leather Complex, our in-house tannery is the foundation of our product quality. This facility holds a GOLD rating from the Leather Working Group (LWG), demonstrating our commitment to environmental best practices. We produce 1.5 million square feet of quality leather per month.

Total Control, Quality.

Gloves Manufacturing Unit

Our Gloves Unit is a fully equipped, modern manufacturing facility designed to deliver precision, protection, and consistency. With advanced machinery, skilled technicians, and rigorous quality-control systems, we produce a wide range of industrial, and safety gloves that meet global standards. Every stage—from material selection to final inspection—is monitored for durability, comfort, and performance. Our continuous investment in innovation and sustainability ensures reliable products trusted by customers across diverse industries.

Workwear Manufacturing Unit

Our Workwear Unit is dedicated to crafting high-quality protective garments with a focus on durability, comfort, and functionality. Equipped with modern cutting, stitching, and finishing technologies, the facility supports efficient production of shirts, trousers, coveralls, jackets, and customized safety apparel. Each piece undergoes strict testing to ensure compliance with international standards while maintaining excellent fit and wearability. With experienced teams and streamlined processes, we deliver dependable, scalable workwear solutions tailored to varied industrial needs.

Empowering Precision with Advanced Automation

Multiple Machines & Technology

Tannery Building

Tanning Drums

Stacking Machine

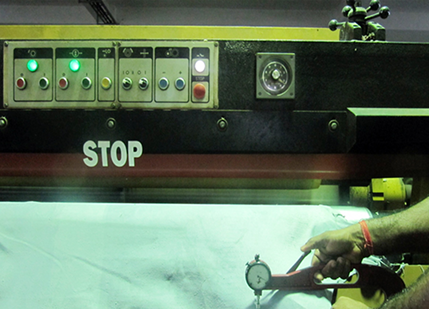

Auto Shaving Machine for Perfect Control of Leather Thickness

Fat Liquor Drums Leather Processing

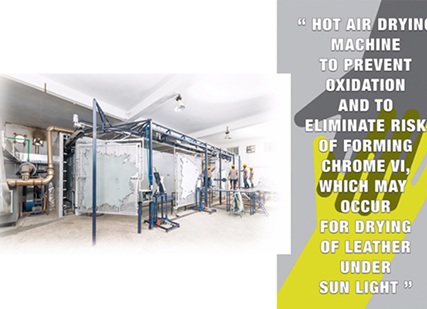

Hot Air Leather Drying Machine

Stacking Machine

Leather Selection and Quality Control

Workplace Safety

Recycling Waste in Eco Friendly Manner

Chrome Recovery Plant

Inhouse Laboratory

Abrasion Test Machine

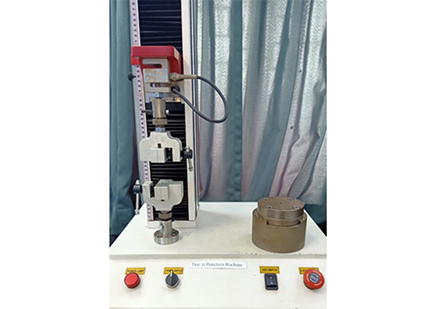

Tear & Puncture Test Machine

PH Control Machine

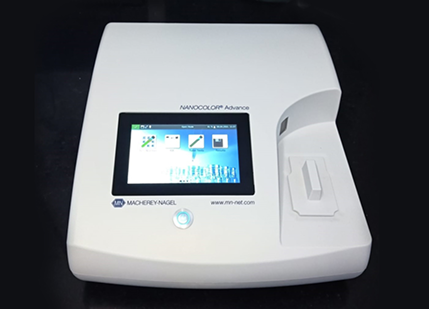

Chrome VI Test Machine

Manufacturing Unit

Cutting

Printing

Stitching

Ironing

Internal Checking & Inspection

Needle Detector Machine

Dehumidifier Room

Tested Rigour

Our In-House Lab

We follow stringent, globally aligned testing protocols to verify product durability, safety, and compliance. Each item undergoes rigorous evaluation to ensure consistent performance across demanding industrial environments.

-

Mechanical Strength Test

Assesses overall durability and resistance under applied force, ensuring the product withstands demanding operational conditions without compromising safety or performance.

-

Determination of Tear Load

Evaluates the maximum stretching capacity before breaking, ensuring materials maintain integrity and performance under tension or heavy load.

-

Tensile Strength

Checks material pH levels to confirm skin safety, regulatory compliance, and absence of harmful chemical residues.

-

Abrasion Resistance

Measures the force required to initiate and propagate tears, confirming material reliability during repeated use and high-stress applications.

-

Determination of pH

Determines surface durability against friction and repeated wear, ensuring long-lasting performance in tough working environments.

-

Testing the Chromium VI Level

Examines leather for hazardous Chromium VI content, ensuring strict adherence to international safety and environmental standards.